Elevate your pharmaceutical procedures to the next amount with KINTEK's large-top quality sieves. Our precision engineering assures exact particle size Assessment, efficient screening, and trustworthy separation of components, all essential for keeping the highest expectations of pharmaceutical top quality and security. You should not compromise to the efficacy and security of the remedies.

Sieves are subjected to tricky use, irrespective of whether in a sieve shaker or with manual sieve approaches. Sample hundreds induce distortion of the woven-wire mesh and abrasion results in a reduction of wire diameters, enlarging the openings past satisfactory limitations. Other available choices for ongoing validation of sieve accuracy and conformity also are readily available:

This can be a large amount of information all of sudden. We’d be joyful to learn about your functions and issues and develop a tailor-made Resolution to your condition. We’ll be in touch!

Can ultrasonic deblinding sieves and separators be tailored to unique field demands? Of course, ultrasonic deblinding sieves and separators might be tailor-made to fulfill the one of a kind wants of varied industries. Russell Finex offers customization options like choosing the suitable display screen product as well as other Make contact with parts, mesh size, and overall design to suit certain applications.

Quite a few things occur into Enjoy On the subject of sieve mesh size. For illustration, the thickness of your wire used during the sieve can have an affect on the mesh size.

This cookie is set by doubleclick.net. The objective of the cookie is to find out Should the person's browser supports cookies.

The E11 ASTM sieve sizes standard gives in-depth mesh designation and design specifications for sieves with a range involving a hundred twenty five mm to twenty micrometers, making certain exact separation of resources for several industries. Employing a sieve shaker makes sure dependable and economical separation of products.

The cookie is ready by GDPR cookie consent to history the consumer consent to the cookies while in the classification "Purposeful".

three. Bar Screen: It is actually used in managing big and large components. These bars are fixed in parallel positions and held by crossbars and spacers.

Sieve size analysis is used to carefully affirm the granular profile of protecting content placed on a steel's floor to safeguard it versus corrosion.

Utilizing a sieve shaker may help sustain the wire fabric’s functionality by guaranteeing even distribution of particles through sieving.

The thickness of your wire fabric content also performs a major position in deciding the mesh size. Thicker wires produce smaller openings, which prohibit the size of particles which will pass through the sieve.

It’s necessary in sieving different components, Every needing a specific mesh size to proficiently separate particles.

How does ultrasonic technological innovation function for deblinding sieves and separators? Ultrasonic deblinding sieves and separators make use of substantial-frequency vibrations created by a transducer mounted immediately on to the mesh monitor. These vibrations here create website a bouncing effect on the sieve floor, preventing particles from sticking or lodging in to the display screen apertures.

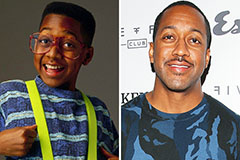

Jaleel White Then & Now!

Jaleel White Then & Now! Yasmine Bleeth Then & Now!

Yasmine Bleeth Then & Now! Gia Lopez Then & Now!

Gia Lopez Then & Now! McKayla Maroney Then & Now!

McKayla Maroney Then & Now! Naomi Grossman Then & Now!

Naomi Grossman Then & Now!